What are TMT Bars?

TMT bars or Thermo-Mechanically Treated bars are high-strength reinforcement bars that have a tough outer core and a soft inner core. They have superior ductility and due to the absence of cold stress, TMT bars are corrosion resistant and possess high weldability.

How is TMT manufactured?

Using the latest and most advanced Thermex (QST) German Technology known as ‘Thermo Mechanical Treatment’, TMT bars are manufactured.

Why TMT bars should be your priority for all your construction projects?

Because they are strong, ductile, corrosion-resistant and economical.

Is the use of TMT bar limited to one industry?

No. Its application is diverse – Power Plants, Dam, Airports, Bridges, Flyovers, Stadiums, Highways, Underground structures, Marine structures, Industrial structures, residential buildings and more.

What are the other specialities of A-One Gold Steel’s TMT bars?

Mechanical Properties

Because of our unique method of manufacturing, our TMT Bars possess a combination of strength and ductility that is far more than the minimum limit specified in the standard IS: 1786. Undoubtedly, these superior values of strength and ductility are of a higher level of safety.

Bendability

The tough outer surface and softcore of A-One Gold TMT Bars result in rebar with excellent Bendability. The bar can be bent easily around mandrels much smaller in diameter than what is specified in IS:1786. This has an obvious advantage at construction sites.

Dimensional Tolerance

A-One Gold TMT Bar is supplied with sectioned weight lower than the nominal value and is not more than 1% heavy. This ensures higher meterage per unit weight as compared to ordinary rebars.

Seismic Resistance

Uniform ductility results in the superior seismic resistant property for A-One Gold TMT Bars.

Corrosion Resistant

TMT Bar is produced by thermo-mechanical treatment and not by cold twisting. Therefore, there is no torsional reducing stress which results in superior corrosion resistance characteristics.

Due to these world-class properties, we are the best TMT manufacturers in South India.

How can one identify real A-One Gold Steel TMT Bar?

Each bar has our logo which depicts the genuineness of our products. Avoid products which do not have our logo endorsed on them while choosing A-One Gold Steel TMT Bars.

How many grades are there in A-One Gold Steel’s TMT bars?

A-ONE THERMEX TMT BARS are produced in Fe 500, Fe 500D, Fe 550D, CRS confirming to IS: 1786 Grade. However, carbon levels are restricted much lower than those confirming to specification, which results in excellent ductility, high bendability and superior weldability. (In case of Weldable Bars, the Carbon content should be 0.25% Max.)

| SECTION WEIGHT | |||||

| Section | A-One Weight Range | Average Wt. of A-One TMT | Average Market Std.Wt. TMT | Saving with A-ONE TMT upto | |

|---|---|---|---|---|---|

| (Kg./Mtr.) | (Kg./Mtr.) | (Kg./Mtr.) | In Weight (Kg./Mtr.) | In % | |

| 8 | 0.367-0.395 | 0.381 | 0.408 | 0.027 | 7.06 |

| 10 | 0.574-0.617 | 0.595 | 0.638 | 0.043 | 7.15 |

| 12 | 0.844-0.888 | 0.866 | 0.91 | 0.044 | 5.12 |

| 16 | 1.501-1.579 | 1.54 | 1.618 | 0.078 | 5.05 |

| 20 | 2.396-2.467 | 2.432 | 2.504 | 0.072 | 2.98 |

| 25 | 3.375-3.755 | 3.795 | 3.907 | 0.112 | 2.96 |

| 32 | 6.121-6.314 | 6.312 | 6.408 | 0.19 | 3.05 |

Why choose A-One Steel Group’s pipes & tubes?

We are proud of our superior quality ERW Steel Pipes and Tubes, which are known for their quality and durability. With the unparalleled features, we are the best pipe & tube manufacturer in South India.

Where can we use Steel pipes & tubes?

ERW Black Steel Pipes and Tubes are used for various engineering purposes, fencing, scaffolding, line pipes etc. Additionally, they can be used in:

- Drip irrigation system

- Fertilizing, spraying pesticides

- Casing for borewell

- Removing sludge

- Husk blowing & grain transfer

- Halls

- Sheds

- Temporary bridges

- Roads

- Stadiums

- Spectator stands

- Podiums

- Transporting oil, gasoline & propane

And many other sectors…

What are the features of your Pipes & Tubes?These Pipes & Tubes are available in various qualities, wall thickness, diameter and finishes depending on the requirement of the end user.

- Grades – IS 4923, & IS 1161

- Sizes – 15NB to 80NB, 20*20 to 72*72, 40*20 to 96*48

- Biggest manufacturing plant in South India with a capacity of 20000 per month

- Mechanical properties – 280mpa to 320 mpa, Elongation upto 20%

- Chemical properties – C-0.07, Mn-0.50, S-<0.04, P<0.03

- Thickness All Size: = 10%

- Outside Dimension of Sides: 1% with a minimum of = / -0.5 mm Weight

- On Individual: + 10%

- On Individual: – 8%

- On Lots of 10 Ton, Nmin: +7.5%

- Squareness of Corners: 90 degree + 2 degrees

- Radii of the Corners-Outside 3t, Max. where “t” is the Thickness of the Section

- Length: +6 mm

- Customised Length ranging from 4 m to 15 m may be supplied

In manufacturing these ERW Pipes and Tubes. we utilize superior quality, continuous casted, fully kilned, fine-grain, control-rolled, low carbon steel.

High Strength Corrosion Resistance, high malleability, superior strength, sturdy & durability are the special features of high performance ERW Steel Pipes & Tubes that are manufactured by us.

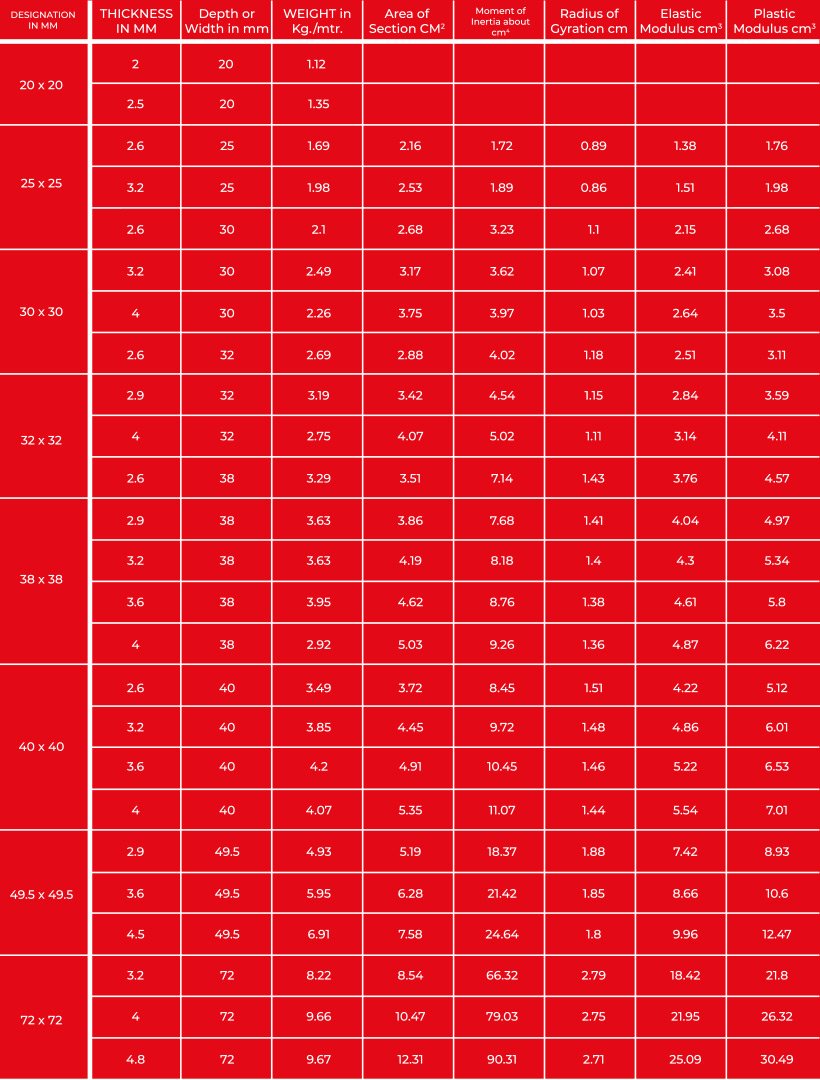

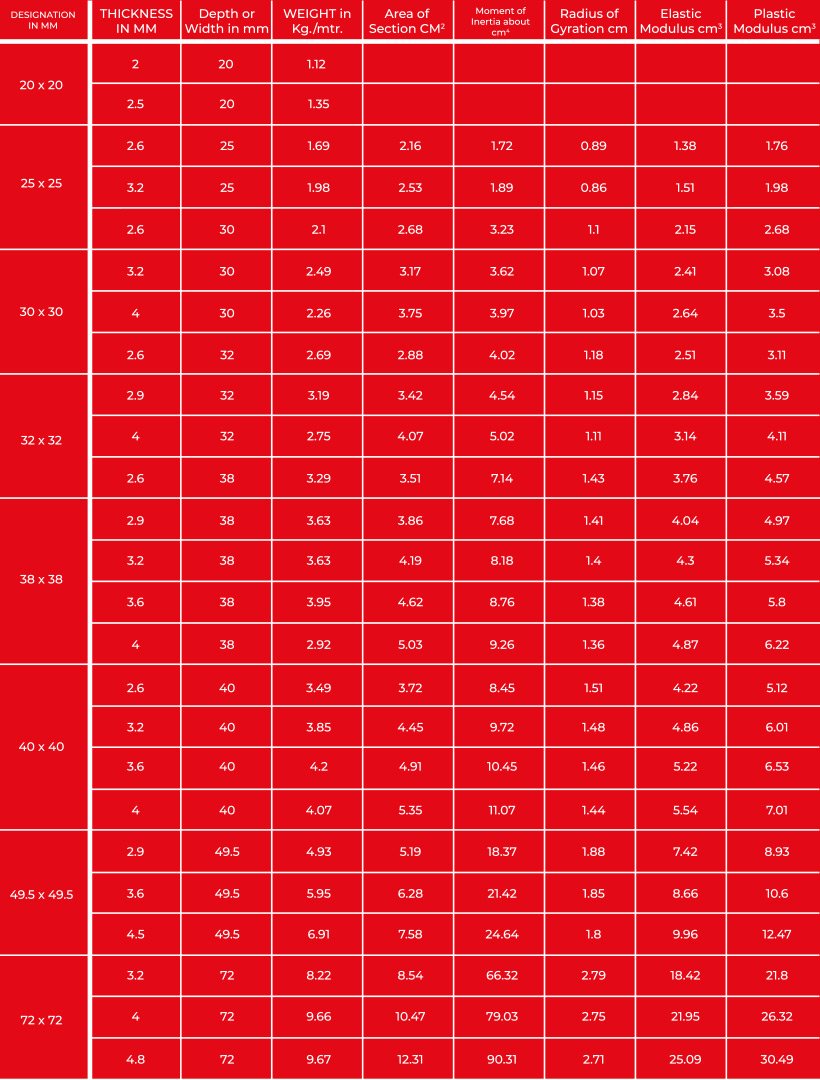

Dimension and Properties of Square Hollow Section:

Dimension and Properties of Rectangular Hollow Section:

Tensile Properties of Hollow Section:

- What is a hot-rolled steel?

- Hot rolled steel is a kind of steel that has been roll-pressed at a very high temperature.

- What are the properties of Hot-rolled steel?

- Slightly rounded edges and corners

- Minor distortions

- Less precise finishings

- More malleable

- Adaptable

- Higher ductility and toughness

- What are the advantages of Hot-rolled steel?

- Improved performance of the metal

- Reduced costs

- Less distortion resistance leading to higher plasticity

- Increased efficiency of the process

- When did we start manufacturing Hot-rolled Steel?

- We started manufacturing Hot Rolled coils in 2018 at our plant in Bellary.

- What are the features of A-One Steel Group’s hot-rolled steel?

- Grade – IS 10748

- Widest range of hot rolled products, with thickness up to 1.2 mm, width up to 400 mm and coil weight up to 2.5 MT

- Widest Hot Strip Mill in South India, capable of rolling up to 400 mm

- Desired cooling patterns achieved using Cooling Tower & Laminar Cooling System

- Made from MS Slab and mainly used for Structural/GP/GI pipe

- Wide Range of sizing options in width and length of Coil

- Hot Charging/LRF/Made from Virgin Material (I/O)

- Equipped with sizing presses and automatic line inspection facility

- How can one identify real A-One Gold Steel Hot-rolled steel?

- Each of our products has our logo which depicts their genuineness. Avoid products which do not have our logo endorsed on them.

- What are the applications of Hot-rolled steel?

- Construction & Infrastructure Industry

- Hotel lobby

- Airport

- Office

- Automotive & Transport Industry

- Truck frames

- Seat frames

- Agriculture Industry

- Harvesters

- Tractors

- Energy

- Gas cylinder

- Fuel & energy complex

- Water heaters

- Engineering

- Shipbuilding

- Heavy engineering

- Railway

- Railcar components

- Railroad tracks & equipment

- Guard rails

- Doors & shelving

- What is Structural Steel commonly known as?

- Structural steel is commonly known as Section Steel.

- What is Structural Steel?

- Structural steel is defined as the steel which is available in various shapes and sizes that is usually used in construction.

- What is the main purpose of Structural Steel?

- Structural Steel is mainly used for the purpose of building Steel Structures

- How are Steel Structures constructed?

- Steel Structures are constructed using these Structural Steel by fabrications as per the requirement and ideas of the Structural Steel engineer.

- What are the important elements present in Structural Steel?

- The most important element of Structural Steel is analysed by its carbon and steel content.

- What are the kinds of Structural Steel?

- Structural Steel is categorized based on its chemical composition as Mild Structural Steel and Carbon-Manganese Steel. The components of Mild Structural Steel are Iron, Carbon and Manganese.

- In what shapes is Structural Steel available?

- Structural Steel is available in a wide range of shapes like Beam, Angle, Channels, Flats and Squares, etc…

- What are the features of Structural Steel?

- Following are the features of Structural Steel:

- High strength

- High ductility

- Superior bendability

- Better weldability

- Following are the features of Structural Steel:

- Where do you need Structural Steel?

- Structural steel finds its usage in the following sectors:

- Construction & Infrastructure Industry

- Aircraft hangers

- Bridges

- Towers

- Industrial sheds

- Warehouses

- Gates, Doors, Grills & Windows

- Residential & commercial buildings

- Energy Industry

- Mining

- Transport Industry

- Automobiles

- Ship building

- Why should you choose A-One Steel Group’ Structural Steel?

- Following are the reasons to choose A-One Steel Group’s Structural Steel:

- Self-sourcing of raw materials

- Integrated manufacturing facility

- In-house research and development centre

- Highly experienced technical team

- Best chemical composition

- Better quality control

- High strength and ductility

- Available in various shapes and sizes

- One stop for all structural steel requirements

- Economically viable

- Following are the reasons to choose A-One Steel Group’s Structural Steel: